Automotive manufacturers are replacing heavy metal parts with high-performance polymers from EMS-GRIVORY in a weight and cost-efficient way. Interior and exterior parts as well as well as power train and chassis components using EMS' materials are up to 30% lighter in weight and 50% lower cost while retaining the same load-bearing capacity and maintaining safety factors. The materials do not corrode, are crash-resistant and provide mechanical values equal to those of metal. In this way, EMS-GRIVORY solutions make a significant contribution towards cost and weight optimization in automotive construction.

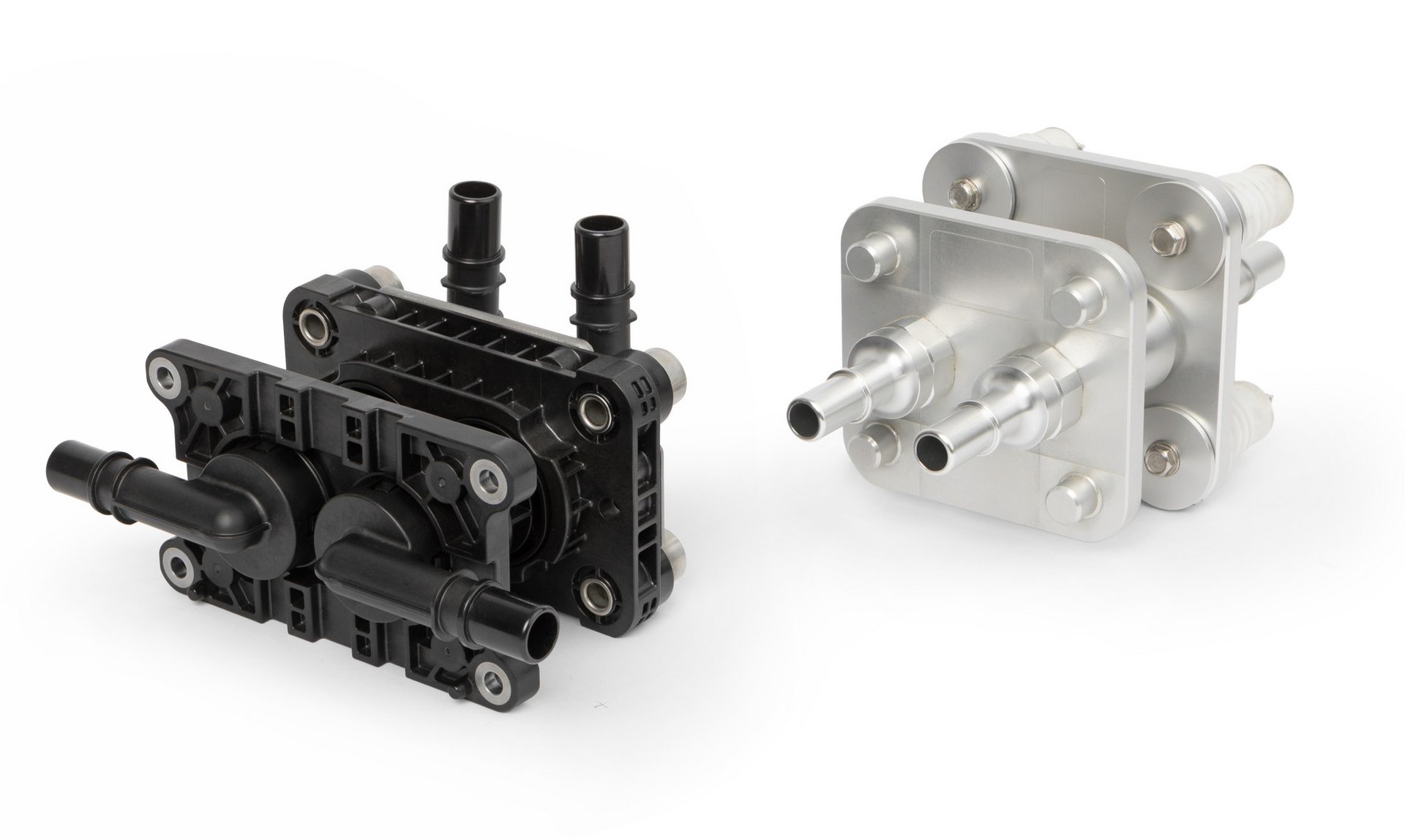

The new quick-connect battery systems for electric vehicles: Made from the EMS high-performance polymer Grivory HT and previously manufactured from aluminum.

Automotive manufacturers are replacing heavy metal parts with high-performance polymers from EMS-GRIVORY in a weight and cost-efficient way. Interior and exterior parts as well as well as power train and chassis components using EMS' materials are up to 30% lighter in weight and 50% lower cost while retaining the same load-bearing capacity and maintaining safety factors. The materials do not corrode, are crash-resistant and provide mechanical values equal to those of metal. In this way, EMS-GRIVORY solutions make a significant contribution towards cost and weight optimization in automotive construction.

Lighter weight vehicles, lower costs, higher sustainability: Metal components in automotive construction are often heavy and expensive, without offering any decisive advantages over modern solutions made using high-performance polymers from EMS. Metal parts require complex post-treatment, their manufacture is energy-intensive and the service life of die-cast molds is limited.

The use of flame-retardant Grivory HT in the new quick-coupling battery system for electric vehicles replaces aluminum and guarantees a safe, leak-free connection of the battery cooling circuit, ideal for automated battery replacement. The polymer-based solution provides weight savings of 40% (from 1.3 kg to 0.8 kg) and enables cost savings of up to 60% to be achieved.

The new ABS valve component made of Grivory HT (PPA) replaces an aluminum part. With over seven million braking cycles, this safety-relevant component exceeds the required service life more than sevenfold and remains dimensionally stable at temperatures between –40 °C and +80 °C. Grivory HT impresses with high strength values, dimensional stability, chemical resistance and metal-like behavior, even in humid environments.

The manufacturing process also provides advantages. The injection molding process involves significantly lower processing temperatures compared to die-cast aluminum. There is no need for time-consuming post-treatment, energy consumption is reduced by 25%, component costs by 30% and weight by 20%. Additional integrated functions and a reliable direct screw connection also simplify assembly. At the same time, the ecological balance is improved; the CO₂ footprint is reduced by around 60%, the component is fully recyclable and developed according to design-for-recycling principles.

For more than 20 years, metal-replacement using high-performance polymer materials from EMS has been a key component of efficient lightweight construction in cars and trucks. Together with its customers, EMS develops customized solutions starting from material selection and component simulation right up to series production. The result is long-lasting, economical and sustainable solutions, which increase efficiency and competitiveness in automotive construction.