At the 23rd SPE Automotive Award Night of the “Society of Plastics Engineers”, EMS-GRIVORY was once again among the winners with one-first and three second places! The award-winning applications made from EMS high-performance polymers demonstrate once again how innovative solutions are created in close cooperation with customers, enabling them to save costs and weight.

1st Place Position Sensor for Electric Vehicle

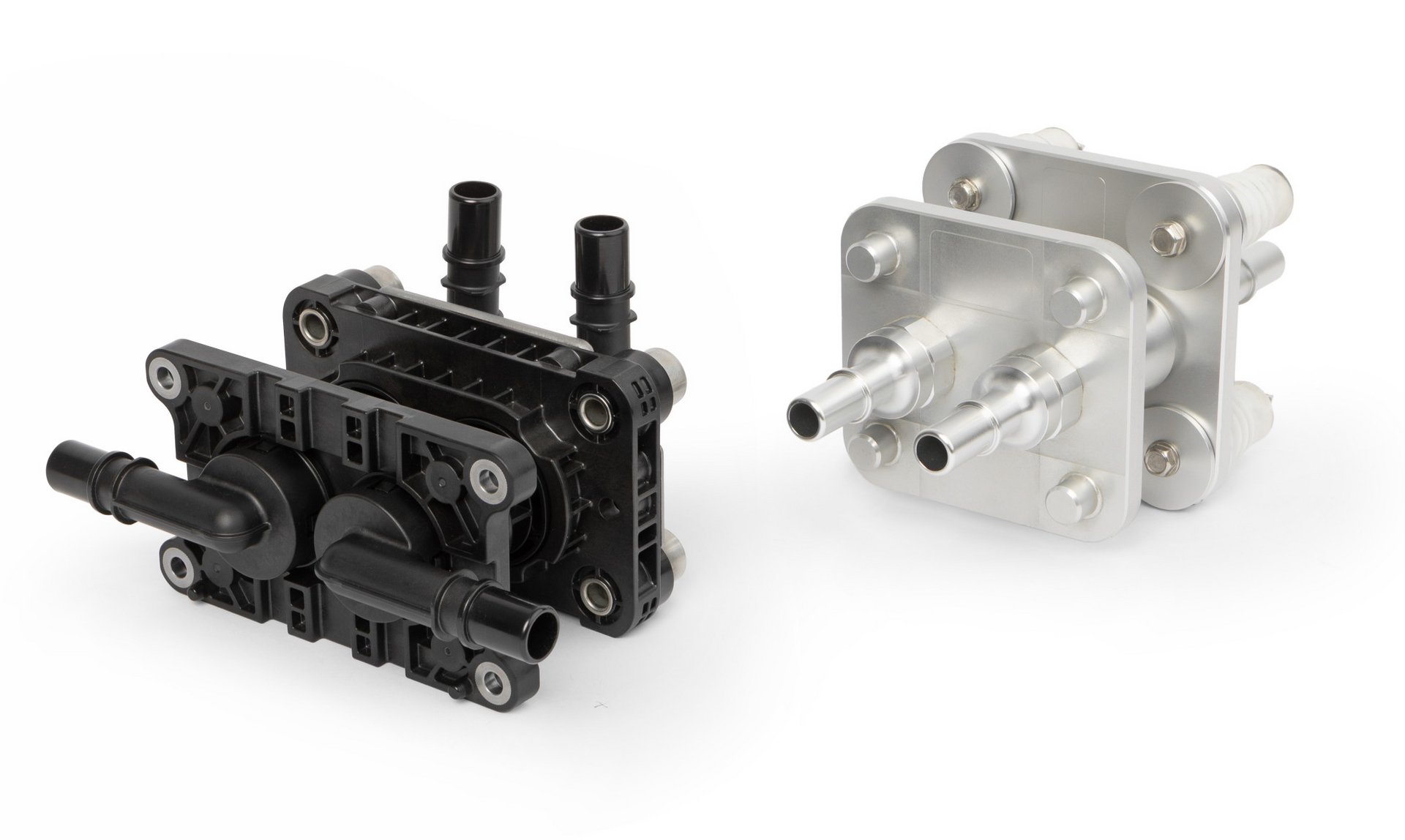

2nd Place ABS Solenoid Valve for Trucks

2nd Place Quick Connector in Thermal Management

2nd Place Crash Protection for Brake System System

At the 23rd SPE Automotive Award Night of the “Society of Plastics Engineers”, EMS-GRIVORY was once again among the winners with one-first and three second places! The award-winning applications made from EMS high-performance polymers demonstrate once again how innovative solutions are created in close cooperation with customers, enabling them to save costs and weight.

At the 23rd SPE Award Night on October 6th, 2025 in Bonn (Germany), the coveted SPE Automotive Awards for the most innovative polymer applications in the automotive industry, were presented once again. This time around, four applications made from EMS materials were awarded the coveted prizes.

The new sensor housing made from Grivory HT1 for electric motors integrates rotor position detection and an effective oil seal in a single component. This reduces installation space and system complexity while fulfilling ASIL D (Automotive Safety Integrity Level) requirements for safety-critical components. The complete solution made from Grivory HT1 withstands temperatures from -40 °C to +155 °C, long-term contact with e-motor oil, and extreme shock and vibration loads. A triple O-ring seal and a specially formulated potting compound ensure maximum tightness and reliable protection for the electronics. By integrating multiple functions, the Grivory solution eliminates additional sealing and housing components compared to aluminum, resulting in significantly lower manufacturing and assembly costs. At the same time, the material consumption and resource use are reduced, leading to a noticeably improved environmental balance. The overall solution thus combines safety, efficiency, and sustainability in a single component.

The new ABS solenoid valve made from Grivory HT1 replaces the aluminum version and offers maximum safety at significantly lower costs and CO₂ emissions. The component weight has been reduced by 33%, and the CO₂ footprint lowered by 60%. The energy-efficient processing saves up to 25% energy, eliminates all post-processing steps, and reduces manufacturing costs by around 30%. At the same time, the valve impresses with more than seven million braking cycles and a service life of up to 20 years, many times the required performance.

In operation, low maintenance requirements, high reliability, and safe functionality throughout the entire service life provide measurable advantages. The ABS solenoid valve combines safety, efficiency, and sustainability in one single solution.

The new quick coupling system enables a reliable, leak-free connection of the cooling circuit between the battery and the vehicle and is designed for automated battery replacement. The optimized flow channel reduces pressure loss in the system, and the modular design allows flexible integration into different vehicle architectures. By using bio-based, V0 flame-retardant Grivory HT3, weight and cost can be significantly reduced, the component is up to 40% lighter and production costs are up to 60% lower compared to the aluminum version.

Switching to injection molding avoids material waste, shortens production cycles, and lowers energy consumption. The use of the biopolymer reduces the CO₂ footprint by around 65%, enables pure material recycling and combines operational safety and process efficiency with a significantly improved environmental profile for sustainable vehicle production.

The new safety-relevant crash protection made from Grivory GVL for the electrohydraulic OneBox brake system reliably protects the electrical connector in the crash area, thereby ensuring the vehicle’s driving dynamics and safety functions even in the event of an accident.

Unlike metal solutions, the Grivory GVL version prevents permanent deformation and short-circuit risks and limits deformation during a crash to a maximum of 6 mm. The design was based on extensive FEM simulations, ensuring optimal long-glass-fiber orientation. A one-piece version is used for left-hand-drive vehicles, whereas right-hand-drive models feature a two-piece design optimized for quick and cost-efficient assembly through direct screwing. This design offers maximum safety in minimal installation space. Crash tests at -40 °C, 23 °C, and 80 °C successfully validated the components under forces exceeding 25 kN. Additional simulations and sled tests were conducted to optimize fiber orientation for maximum energy absorption. This crash protection solution impressively demonstrates the high-performance potential of Grivory GVL in crash-relevant applications, especially where metal cannot be used due to deformation or short-circuit risks.